The importance of the pharmaceuticals and healthcare industries has never been more apparent than in the current times. The benefits of effective medications, as well as reliable tests to the consumer are huge and are in many ways a key part of life. However, delivering this is becoming harder due to the sensitive nature of the goods together with the high volumes that need delivering.

Currently there is over 1 million Covid19 tests being conducted each day and over 140,000 vaccines delivered each day. Even pre-pandemic, blood and pathogen tests equalled more than 1 billion per year and 1.12 billion prescriptions being delivered per year. All these rely on the products not being tampered with or altered at any stage before the time of delivery. For this reason, tamper evident labels can play a key role in maintaining the integrity of products in such complex supply chains.

Tamper evident labels can be used across a wide range of applications in the pharmaceutical industry and have some key elements which make them both practical and essential. Firstly, availability comes in residue and non-residue options depending upon preference. They can also be applied to a wide range of materials such as cardboard, coated card, metal, plastic, polyethylene, glass and painted metal. The labels can also be supplied in various roll widths and lengths, with options for customised design to suit specific requirements.

This adaptability allows the tamper evident labels to secure a diverse range of items such as test-tubes, vials, inner packaging through to outer packaging, pill boxes, cartons and more across the healthcare industry.

Why use Tamper Evident solutions?

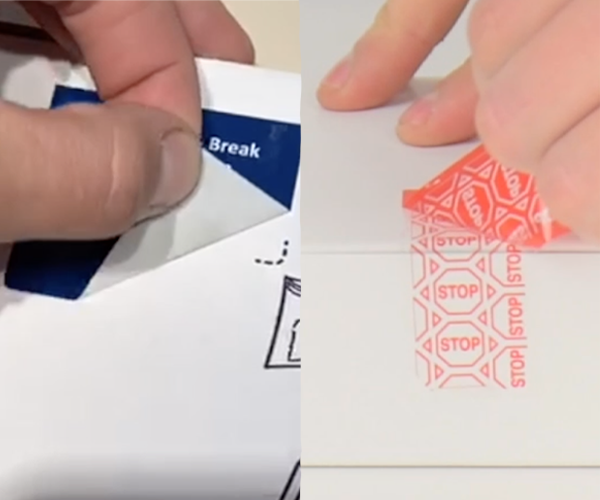

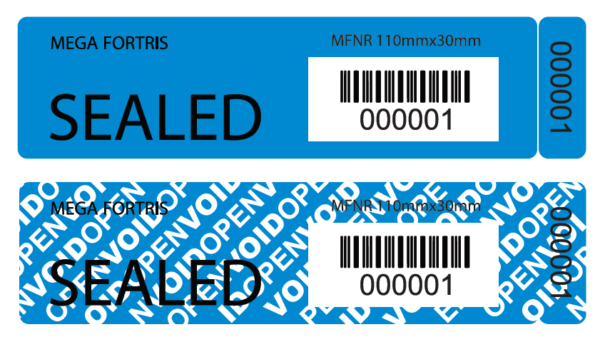

Using tamper evident labels over standard solutions will add an extra layer of security, indicating any signs of tampering. When a normal label is lifted from an application no residue is left and the label itself can be reapplied, leaving goods open to being pilfered or counterfeited without clear signs. Tamper evident labels on the other hand will show a clear void messaging on the application or label face when removed, clearly indicating that the contents could have been tampered with or contaminated. It is also impossible to reapply the label once it has been removed. This key difference provides an important security aspect and provides the consumer / business reassurance of the efficacy of the product.

Tamper evident labels offered

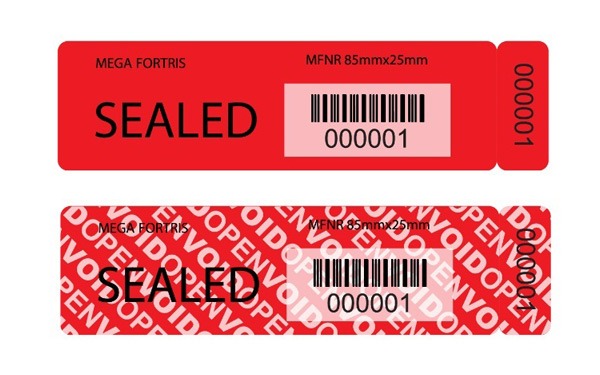

Mega fortris can supply tamper evident labels with customisation options for sizes, sequential numbers, barcodes, QR codes, logos, colours for an overt or covert design and roll lengths.

We provide 3 standard size options on our website in Non-transfer and partial transfer.

Non-Residue

Non-Residue Security Label 110mm x 30mm

Non-Residue Security Label 85mm x 25mm

The products show a tamper evident void message on the label face after being lifted from the application surface. No residue is left on the application surface and the label cannot be re-applied once removed.

Partial Residue Security Label 85mm x 25mm

This product leaves a residue void message on the application surface and shows a void message on the label surface. The label cannot be reapplied once removed.

We can supply tamper evident labels in a wide range of sizes and customisations, contact our team for more information and enquiries.

Recent Comments